OAV MAX 370P Rapidedge Pro edgebaning machine

OAV versatile edge bander can quick change edge 0.5 mm 1 mm and 2 mm within the user-friendly touch panel.

Are you tired of spending valuable production time adjusting

your edge bander to run various edge banding material?

Do you want a professional-grade edge banding machine that can work quickly and efficiently?

Look no further than the RapidEdge Pro edge bander! Our top-of-the-line solution is designed to make edge banding a breeze. With its advanced technology and user-friendly interface, the RapidEdge Pro can apply edge banding to your projects in record time, without sacrificing quality or accuracy. Its compact size and easy-to-maneuver design makes it the ideal edge banding solution for use in any workshop or manufacturing setting.

Here are just a few of the outstanding features that make the RapidEdge Pro stand out from the rest:

Don’t settle for an inferior edge banding machine solution that slows you down and produces sub-standard results? Upgrade to the RapidEdge Pro today and experience the difference for yourself!

Do you want a professional-grade edge banding machine that can work quickly and efficiently?

Look no further than the RapidEdge Pro edge bander! Our top-of-the-line solution is designed to make edge banding a breeze. With its advanced technology and user-friendly interface, the RapidEdge Pro can apply edge banding to your projects in record time, without sacrificing quality or accuracy. Its compact size and easy-to-maneuver design makes it the ideal edge banding solution for use in any workshop or manufacturing setting.

Here are just a few of the outstanding features that make the RapidEdge Pro stand out from the rest:

- Rapid application: The RapidEdge Pro can apply different thickness of edge band from 0.5 mm, 1 mm to 2 mm to your projects with rapid changeover speed allowing for optimal production output.

- Precision accuracy: With its advanced trimming system, the RapidEdge Pro ensures that your edge banding is perfectly aligned and trimmed every time.

- Easy operation: The RapidEdge Pro's intuitive interface makes it easy for anyone to operate, regardless of skill level or experience.

- Durable construction: Our machine is built to last, with sturdy components that can withstand the rigors of daily use.

Don’t settle for an inferior edge banding machine solution that slows you down and produces sub-standard results? Upgrade to the RapidEdge Pro today and experience the difference for yourself!

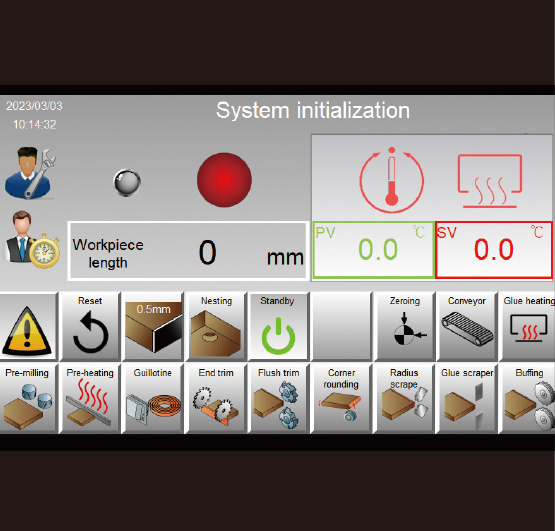

Touch screen

HMI control system reduces manual settings to a minimum and enables a quick, easy and intuitive selection and control of the aggregate as well as the complete monitoring of all machine functions from the screen.

HMI control system reduces manual settings to a minimum and enables a quick, easy and intuitive selection and control of the aggregate as well as the complete monitoring of all machine functions from the screen.

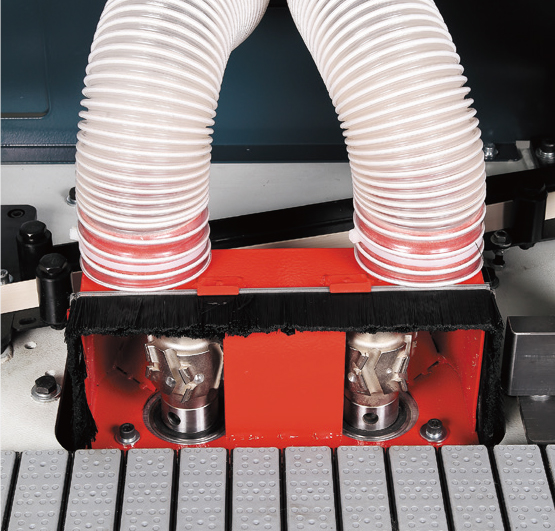

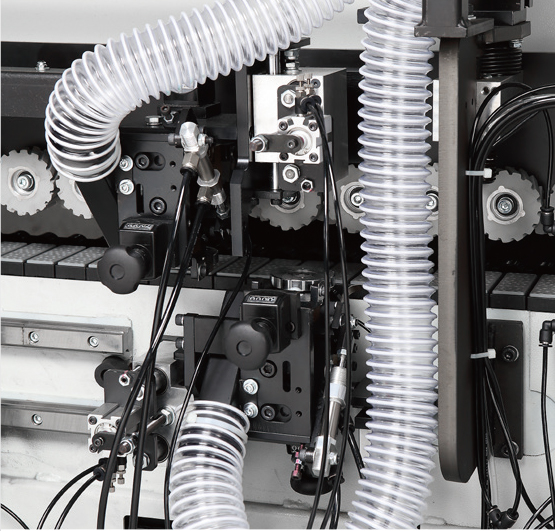

Pre-milling unit

Two counter rotating activation controlled and individually adjustable units with spiral cutters that ensure first class edge processing before the workpiece is glued to the edge.

Two counter rotating activation controlled and individually adjustable units with spiral cutters that ensure first class edge processing before the workpiece is glued to the edge.

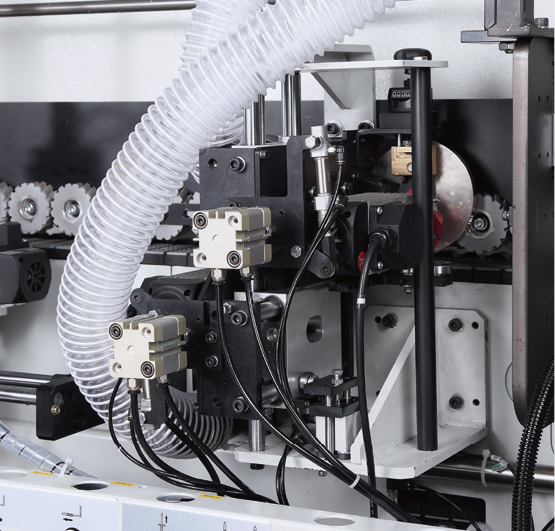

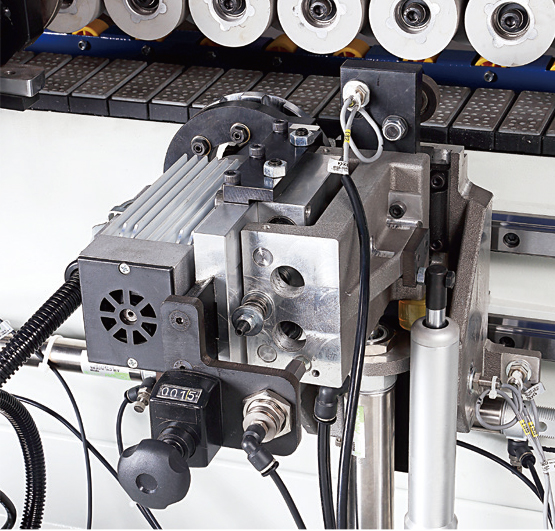

Quick change glue pot

The Teflon coating glue pot has 1.2 kgs capacity, short warm-up time is quick operational readiness. The quickly change system of the glue pot guarantees shortest cleaning and changeover time when changing glue.

The Teflon coating glue pot has 1.2 kgs capacity, short warm-up time is quick operational readiness. The quickly change system of the glue pot guarantees shortest cleaning and changeover time when changing glue.

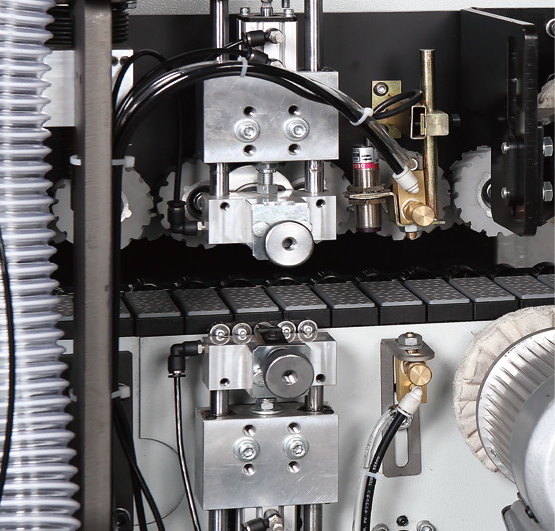

End cutting unit

Two blades with fence plate against workpiece to cut excessive edge on the front and rear sides.

Two blades with fence plate against workpiece to cut excessive edge on the front and rear sides.

Flush trimming

Two counter rotating activation controlled and individually adjustable units with replaceable knifes that cutting excessive on the top and bottom sides.

Two counter rotating activation controlled and individually adjustable units with replaceable knifes that cutting excessive on the top and bottom sides.

Corner rounding unit

The corner rounding unit is controlled from the control panel, naturally with the option of choosing which corners need to be rounded.

The corner rounding unit is controlled from the control panel, naturally with the option of choosing which corners need to be rounded.

Radius scrap unit

The radius surface receives a light scraping, removing any remaining from the trimming process and ensuring a smooth finish. The fine adjustment is manual.

The radius surface receives a light scraping, removing any remaining from the trimming process and ensuring a smooth finish. The fine adjustment is manual.

Flat scrap unit

Slightly remove residual glue on the workpiece caused by squeeze-out.

Slightly remove residual glue on the workpiece caused by squeeze-out.

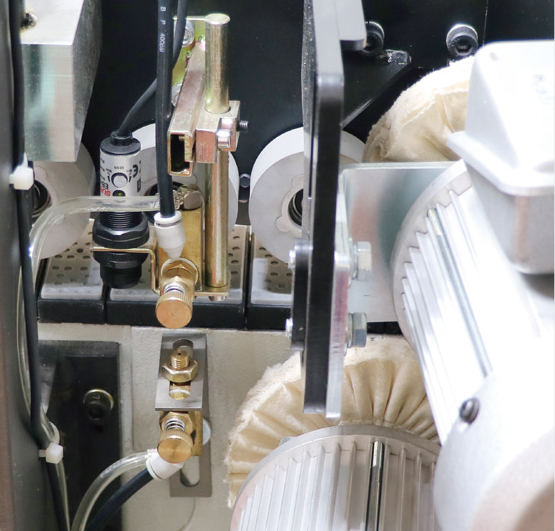

Buffing unit

The unit is made up of two independent electric motors, which are equipped with cotton brushes.

The task of the buffing unit is to clean and polish the top and bottom part of the edge.

The unit is made up of two independent electric motors, which are equipped with cotton brushes.

The task of the buffing unit is to clean and polish the top and bottom part of the edge.

Nesting function

Nesting kits is good for the workpieces will be already drilled before edgeprocessing.

Nesting kits is good for the workpieces will be already drilled before edgeprocessing.

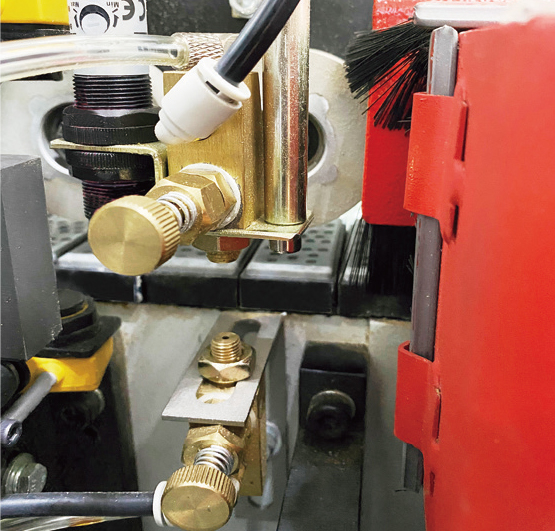

Release agent spray unit (Optional)

Applying release agent from the top and bottom to prevent leaked adhesive residual glue sticking on the workpiece.

Applying release agent from the top and bottom to prevent leaked adhesive residual glue sticking on the workpiece.

Cleaning spray unit (Optional)

Cleaning agent system sprays solvent firm top and bottom of workpieces. Cleaning agent is installed in front of buffing unit and is loose adhesive residue on the panel.

Cleaning agent system sprays solvent firm top and bottom of workpieces. Cleaning agent is installed in front of buffing unit and is loose adhesive residue on the panel.

| MODEL | MAX 370 RapidEdge Pro |

|---|---|

| Feeding speed | 9 M/min. |

| Panel Thickness | 8-45 mm |

| Edge Thickness | 0.4-3 mm |

| Mini. Panel width | 90 mm |

| Mini. Panel length | 170 mm |

| Working table height | 960 mm |

| Extensible support width | 560 mm |

| Extension connector Ø in mm | ø5" (125 mm) |

| Motor | 6.7 kw |

| Pre-milling | 12000 rpm |

| End trimming | 12000 rpm |

| Flush trimming | 12000 rpm |

| Corner rounding | 12000 rpm |

| Buffing | 3000 rpm |

| Packing size | 3960 x 720 x 1748 mm |

| Weight, N.W./ G.W. | 905 kgs / 1190 kgs (N.W./ G.W.) |

| MODEL | POWER (KW) OF EACH MOTOR |

|---|---|

| Feeding motor | 1.5 kw |

| Glue pot heating (5 elements) | 1.315 kw |

| Pre-milling motor | 1.5 kw |

| Pre-heating | 0.4 kw |

| Glue spindle motor | 0.25 kw |

| End trimming | 0.22 kw |

| Flush trimming | 0.37 kw x 2 |

| Corner rounding motor | 0.37 kw |

| Upper / lower buffing motor (each) x2 | 0.12 kw (3 ph), 0.18 kw (3 ph) |

The specifications and design characteristics shown in this catalog are subject to change without prior notice.