ECT 6 SERIES -- CE 作榫机

双端榫机

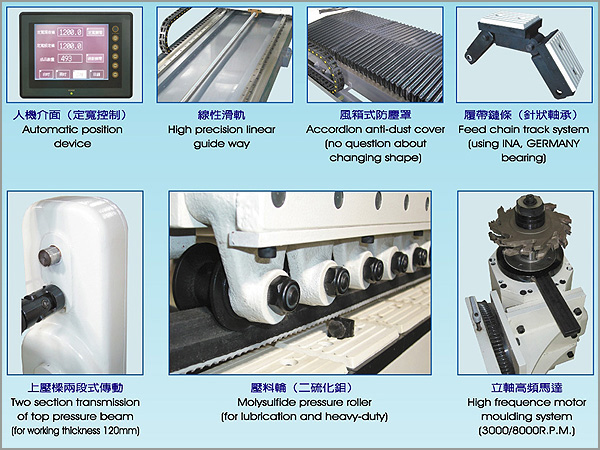

ECT SERIES was born by the highly quality and the strongly structure. The Pursuit of a high quality policy is shown by using of highly precision components and severe inspection procedures to ensure sizing, squiring and tenoning. High-frequency motors which have 8000 R.P.M. are used by moulding unit system to improve precision cutting. This machine definitely widely be used on producing for solid wood and panel furniture, such as: bedroom furniture, office furniture, kitchen furniture, window/door and solid parquet, strength wood flooring.

| Specification | Model | ECT-86S | ECT-66S | ECT-46S | ECT-88S | ECT-68S | ECT-48S | |

| Max. Working Width | mm | 2600 | 2000 | 1300 | 2600 | 2000 | 1300 | |

| Min. Working Width | mm | 210 | 210 | 210 | 210 | 210 | 210 | |

| Max. Working Thickness | mm | 120 | 120 | 120 | 120 | 120 | 120 | |

| Working Units | pcs | 6 | 6 | 6 | 8 | 8 | 8 | |

| Scoring Saw Unit | Motor Horse Power | HP | 2 (3/5) | 2 (3/5) | 2 (3/5) | 2 (3/5) | 2 (3/5) | 2 (3/5) |

| Spindle Speed | R.P.M | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | |

| Spindle Dimension | mm | 25.4 | 25.4 | 25.4 | 25.4 | 25.4 | 25.4 | |

| Sawblade Dimension | mm | 120-205 | 120-205 | 120-205 | 120-205 | 120-205 | 120-205 | |

| Main Saw Unit | Motor Horse Power | HP | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) |

| Spindle Speed | R.P.M | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | 3450 / 60HZ | |

| Spindle Dimension | MM | 25.4 | 25.4 | 25.4 | 25.4 | 25.4 | 25.4 | |

| Sawblande Dimension | MM | 305 | 305 | 305 | 305 | 305 | 255 | |

| Moulding System | Motor Horse Power | HP | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) | 5 (7.5) |

| Spindle Speed | R.P.M | 3000 / 8000 | 3000 / 8000 | 3000 / 8000 | 3000 / 8000 | 3000 / 8000 | 3000 / 8000 | |

| Spindle Dimension | mm | 40 | 40 | 40 | 40 | 40 | 40 | |

| Cutter Dimension | mm | Max.210 | Max.210 | Max.210 | Max.210 | Max.210 | Max.210 | |

| Chain Track System | Motor Horse Power | HP | 2 | 2 | 2 | 3 | 3 | 3 |

| Feed Speed | m/min | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | 6-25 | |

| Distance Between Dogs | mm | 400 (200) | 400 (200) | 400 (200) | 400 (200) | 400 (200) | 400 (200) | |

| Movable Side Shifting System |

Motor Horse Power | HP | 1 | 1 | 1 | 1 | 1 | 1 |

| Feed Speed | m/min | 2 | 2 | 2 | 2 | 2 | 2 | |

| Weight | N.W. | KGS | 4350 | 3900 | 3500 | 4600 | 4200 | 3800 |

| G.W. | KGS | 5000 | 4750 | 4200 | 5350 | 5000 | 4500 | |

| Dimention | Machine Size( LxWxH ) | mm | 4720x4340x1470 | 4120x4340x1470 | 3400x4340x1470 | 4720x4985x1470 | 4120x4985x1470 | 3400x4985x1470 |

| Packing Size( LxWxH ) | mm | 4730x2270x1800 | 4300x2270x1800 | 3520x2270x1800 | 4850x2270x1800 | 4730x2270x1800 | 3550x2270x1800 | |

· Safety Cabinet

· Central Supporter

· Central Supporter with Pressure Beam Supporter

· Automatic Feeding Magazine

· Strengthened Track

· Positioning Knife for Moulding Unit

· Top & Bottom Fences for Working Units

· Extra Dogs – Distance from 400mm to 200mm

· Manual Lubrication Device for Movable Stand

· Automatic Lubrication Device for Movable Stand

· Enlarged Motors

· CE Standard

· Dust Conveyer

· Chopping Saw for the Main Saw

· Central Supporter

· Central Supporter with Pressure Beam Supporter

· Automatic Feeding Magazine

· Strengthened Track

· Positioning Knife for Moulding Unit

· Top & Bottom Fences for Working Units

· Extra Dogs – Distance from 400mm to 200mm

· Manual Lubrication Device for Movable Stand

· Automatic Lubrication Device for Movable Stand

· Enlarged Motors

· CE Standard

· Dust Conveyer

· Chopping Saw for the Main Saw