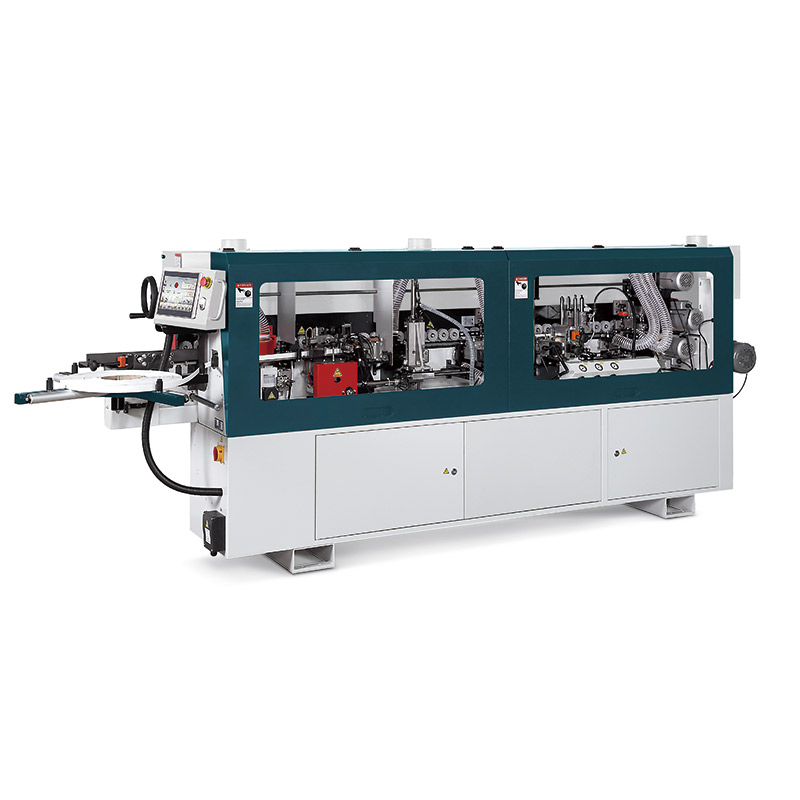

OAV MAX370A Automatic edgebaning machine

A heavy-duty edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen

OAV's Edge Bander MAX370A is the industrial choice with CORNER ROUNDING function which brings you the perfect high-quality result on the workpiece. In coils up to 3mm thick, and strip up to 4mm thick, this affordable machine is equipped with 1.2KG capacity glue tank, premilling, auto gluing, edge cutting, end trimming, flush trimming and scraping, and buffing functions.

Featuring a user-friendly adjustment with numerical indicators as well as TOUCH SCREEN (optional) display for all operation, PLC parameter setting & temperature control, allows for stable and reliable working conditions which will raise the quality of your products while also saving time.

This best choice is the helper to optimize your investment and take your organization's output and performance to the next level!

Featuring a user-friendly adjustment with numerical indicators as well as TOUCH SCREEN (optional) display for all operation, PLC parameter setting & temperature control, allows for stable and reliable working conditions which will raise the quality of your products while also saving time.

This best choice is the helper to optimize your investment and take your organization's output and performance to the next level!

Heavy-duty Chain Feeder

The steady work-piece feeding mechanism is comprised of a chain and set of drive rollers, which will leave no scratches on the work-piece surface.

Pre-milling Unit

The function of premilling can remove up 1 mm panel edge. It removes breakout from the saw, solves out erros caused by a miss set scribing blade or bad cutting panel.

Glue Pot Unit

The 1.2kgsTeflon-coated glue pot is designed for EVA hot-melt glue. The glue is applied with an adjustable glue roller.

End Cutting Unit

This unit is mounted on high-precision linear bearing, which ensure perfect cutting results. The high frequency motors 12,000 RPM motor meets any challenge.

Flush and Radium Trimming Unit

The biggest advantage of the new multi functional combination unit is the amount of space it saves in the machine. The adjustment of the settings from flush to beveled finish for thin edges. as well as radius trimming for thicker edges, is quick and easy. TC 2 mm radius tooling is included as standard.

The Corner Rounding Unit

it is completes the finish of the corners of workpiece, meets the edge material from 0.4-3 mm and 45mm height with same speed.

Buffing Unit

The buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, \vhich is especially noticeable when working with dark edge material.

Radius Scrap Unit

(Flat Scrap Unit as option) The scrping unit fine-tunes the edge radius and remove excess glue.

| MODEL | MAX370A |

| Feeding speed | 9M/min. |

| Panel Thickness | 8-45mm |

| Edge Thickness | 0.4-3mm |

| Mini. Panel width | 90mm |

| Mini. Panel length | 170mm |

| Working table height | 940mm |

| Extensible support width | 560mm |

| Extension connector Φ in mm | Φ5" (125mm)X3 |

| Total kW | 7.4 kW |

| Pre-milling | 12000 rpm |

| End trimming | 12000 rpm |

| Up/down trimming | 12000 rpm |

| Corner Rounding | 12000 rpm |

| Buffing | 3400rpm(60HZ)/2800rpm(50HZ) |

| Overall Size (LXWXH) | 4088x 1003x 1970mm |

| Weight, N.W./G.W. | 870/985kgs(N.W./G.W.) |

| Container Qty' (20'/40') | 3/9 sets |

| Power (kW) of each motor | |

| Feeding Motor | 0.75kW(3ph) |

| Pre-milling | 1.10kWx2 |

| Pre-heating | 0.125kW |

| Glue spindle motor | 0.25kW |

| End trimming motor | 0.22 kW |

| Upper/lower trimming motor (each)x2 | 0.37 kW |

| Corner Rounding motor | 0.37KW |

| Upper/lower buffing motor (each) x2 | 0.12kW (3ph) |

| Glue Pot heating (5 elements) | 1.315 kW |