MAX350M Information

OAV's Edge Bander MAX350M is the compact machine choice with pre-milling function.

In coils up to 3mm thick, and strip up to 4mm thick, this affordable machine is equipped with 1.2KG capacity glue tank, auto gluing, edge cutting, pre-milling end trimming, flush trimming and scraping, and buffing functions. Featuring a user-friendly adjustment with numerical indicators as well as an LCD display for temperature control, 7M feeding speed. It allows for stable and reliable working conditions which will raise the quality of your products while also saving time

OAV's Edge Bander MAX350M is the compact machine choice with pre-milling function.

In coils up to 3mm thick, and strip up to 4mm thick, this affordable machine is equipped with 1.2KG capacity glue tank, auto gluing, edge cutting, pre-milling end trimming, flush trimming and scraping, and buffing functions. Featuring a user-friendly adjustment with numerical indicators as well as an LCD display for temperature control, 7M feeding speed. It allows for stable and reliable working conditions which will raise the quality of your products while also saving time

Specifications

| MODEL | MAX350M |

| Feeding speed | 7M/min. |

| Panel Thickness | 12-45mm |

| Edge Thickness | 0.4 - 3mm |

| Mini. Panel width | 90mm |

| Mini panel length | 90mm |

| Working table height | 856mm |

| Extensible support width | 560mm |

| Extraction connector Ø in mm | Ø4" |

| Total Motor Power | 6.0kw-1PH ; 5.75 kw-3PH |

| Overall Size (LxWxH) | 3200x1200x1200mm |

| Weight, kg (with standard equipment) | 500kgs/632kgs (N.W./G.W.) |

| Packing size (LxWxH) | 2820x720x1320mm |

| Container Qty (20'/40') | 6sets/12sets |

| Pre-milling | 9000rpm |

| Up/down | 10500rpm |

| Front/rear | 8800rpm |

| Buffing | 2800rpm |

| Power (kW) of each motor | |

| Feeding motor | 0.75 (Kw) |

| Glue spindle motor | 0.25 (Kw) |

| Front/rear trimming motor | 0.18 (Kw) |

| Flush trimming motor | 0.55 (Kw) |

| Upper buffing motor | 3ph-0.12 (Kw); 1ph-0.18(Kw) |

| Lower buffing motor | 3ph-0.12 (Kw); 1ph-0.18(Kw) |

| Pre-heating | 0.4 (Kw) |

| Glue pot heating (5 elements) | 1.315 (Kw) |

Overview

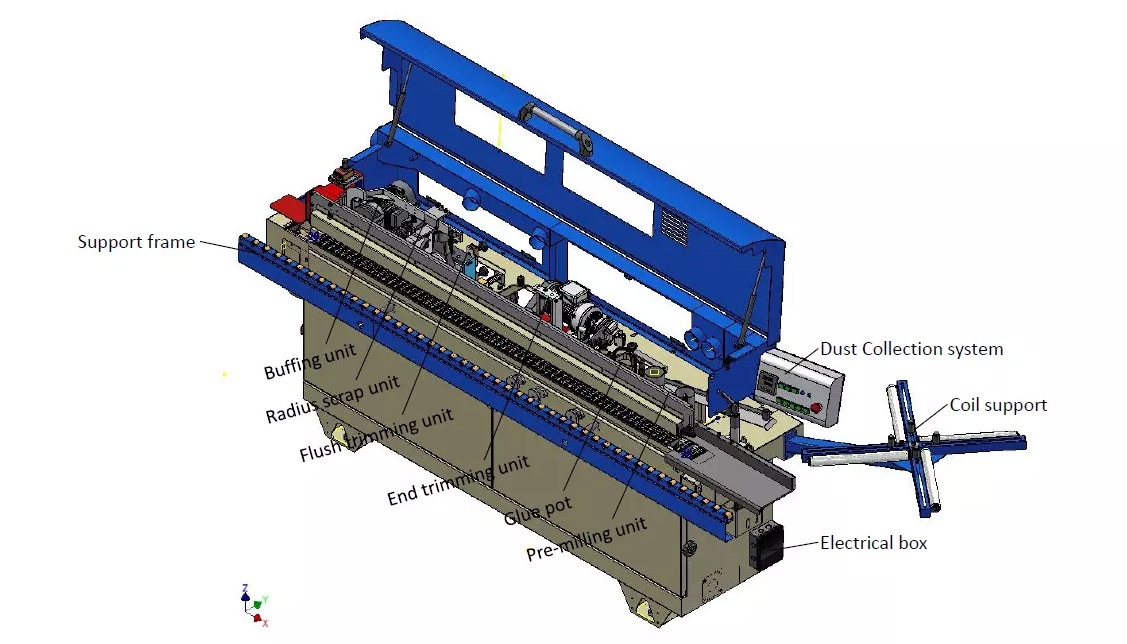

Workspace Description

Glue PotThe 1.2 kg Teflon-coated glue pot is designed for EVA hot-melt glue. The glue is applied with an adjustable glue roller

Glue PotThe 1.2 kg Teflon-coated glue pot is designed for EVA hot-melt glue. The glue is applied with an adjustable glue roller Guillotine ShearsCoiled material up to 3 mm in thickness can be trimmed by the guillotine shears.

Guillotine ShearsCoiled material up to 3 mm in thickness can be trimmed by the guillotine shears.

Pressure RollerThe pressure roller unit is to improve the bond between the edge and the material. The unit is mechanically spring-loaded and due to the •Quick" setup system, can be adjusted exactly to the required edge thickness.

Pressure RollerThe pressure roller unit is to improve the bond between the edge and the material. The unit is mechanically spring-loaded and due to the •Quick" setup system, can be adjusted exactly to the required edge thickness. End Cutting UnitThe unit is mounted on high-precision linear bearings, which ensure perfect cutting results. The high frequency 12,000 RPM motor meets any challenge, regardless of edge type and thickness.

End Cutting UnitThe unit is mounted on high-precision linear bearings, which ensure perfect cutting results. The high frequency 12,000 RPM motor meets any challenge, regardless of edge type and thickness.

Flush and Radium Trimming UnitThe biggest advantage of the new multi• functional combination unit is the amount of space it saves in the machine. The adjustment of the settings from Oush to beveled finish for thin edges, as well as radius trimming for thicker edges, is quick and easy. TC 2 mm radius tooling is included as standard.

Flush and Radium Trimming UnitThe biggest advantage of the new multi• functional combination unit is the amount of space it saves in the machine. The adjustment of the settings from Oush to beveled finish for thin edges, as well as radius trimming for thicker edges, is quick and easy. TC 2 mm radius tooling is included as standard. Scraping UnitRadius Scraping Unit The scraping unit fine-tunes the edge radius and removes excess glue.

Scraping UnitRadius Scraping Unit The scraping unit fine-tunes the edge radius and removes excess glue.

Buffing UnitThe buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, which is especially noticeable when working with dark edge material.

Buffing UnitThe buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, which is especially noticeable when working with dark edge material. Heavy-duty Chain FeederThe steady work-piece feeding mechanism is comprised or a chain and set or drive rollers, which will leave no scratches on the work-piece surface.

Heavy-duty Chain FeederThe steady work-piece feeding mechanism is comprised or a chain and set or drive rollers, which will leave no scratches on the work-piece surface.

OAV MAX350M Automatic Edge Bander Machine

Company Profile

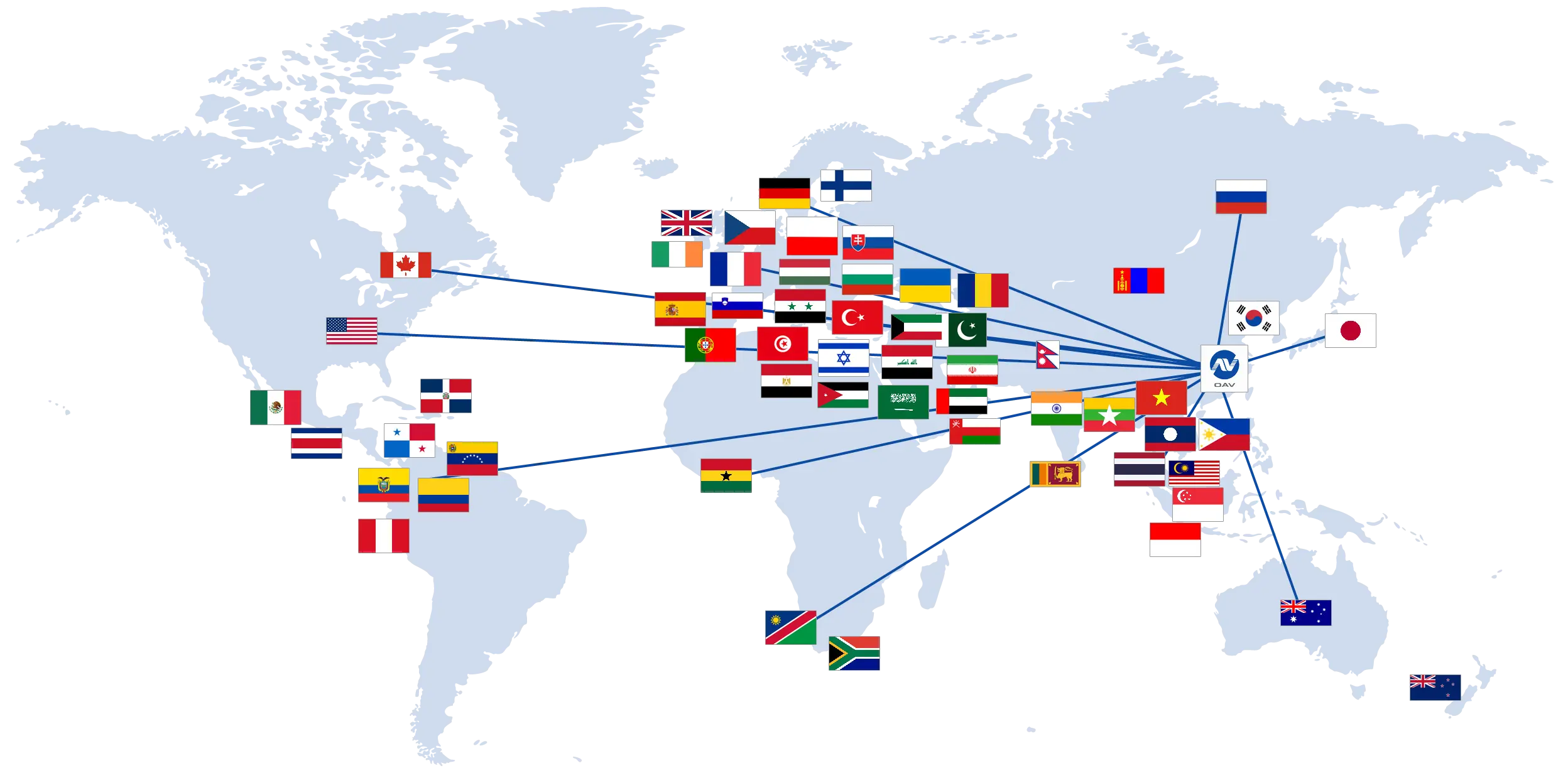

As time passes, business becomes more and more competitive. Success lies in the ability to produce quality goods at competitive prices. OAV Equipment & Tools Inc. is constantly working hard to improve and strengthen its corporate structure and meet new challenges.Since its establishment in 1980, the top priority of OAV has been to provide the highest level of customer satisfaction possible. OAV continues this process today with state of the art facilities, a diversified product range, and the most rigorous quality control process in the industry. At the same time, there is more to

OAV than high manufacturing standards. It is our dedicated staff that sets us apart, each of them bringing their passion and unique talents to the company.At OAV, our focus is not only to improve product quality, but to also make strides in research and development, customer service, and sales. Our greatest strength is our dedication to offering the best possible service to meet the needs of customers all over the world. We spare no effort to ensure that each of our customers receives the highest possible level of customer satisfaction.The people of OAV are devoted to the pursuit of excellence in all stages of the manufacturing process, as well as post-sale services. We strive to make our sales team easy to work with for every customer, regardless of language barriers or cultural differences. Our sales representatives regularly undergo training in order to meet any challenges that may present themselves while working with customers from all over the world. We pride ourselves in continuously improving all aspects of our business structure in order to keep pace with, and eventually set, international standards.

OAV than high manufacturing standards. It is our dedicated staff that sets us apart, each of them bringing their passion and unique talents to the company.At OAV, our focus is not only to improve product quality, but to also make strides in research and development, customer service, and sales. Our greatest strength is our dedication to offering the best possible service to meet the needs of customers all over the world. We spare no effort to ensure that each of our customers receives the highest possible level of customer satisfaction.The people of OAV are devoted to the pursuit of excellence in all stages of the manufacturing process, as well as post-sale services. We strive to make our sales team easy to work with for every customer, regardless of language barriers or cultural differences. Our sales representatives regularly undergo training in order to meet any challenges that may present themselves while working with customers from all over the world. We pride ourselves in continuously improving all aspects of our business structure in order to keep pace with, and eventually set, international standards.

Targeted Market

Our Certificate

Workshop

Packaging & Shipping

FAQ

- 1.Do you have your own factory or trading company?We have 3 factories in Taiwan, are specialized to produce all kinds of woodworking machinery.

- 2.Can you offer high quality product?Quality is an important factor when it comes to any product or service. Quality control is essential to building a successful business that delivers products that meet or exceed customers' expectations. Quality is our responsibility and we care about it very much.

- 3. What’s your warranty?We offer one year warranty, including spare parts are given free replacement if the defective of goods or parts is solely duty of us. Our service team will offer on line service and give solution within 12-24 hours.

- 4.How to install?All OAV’s machines are adjusted well before we deliver, inside packing, we will offer detailed operation manual for reference, also video will be offered if necessary.