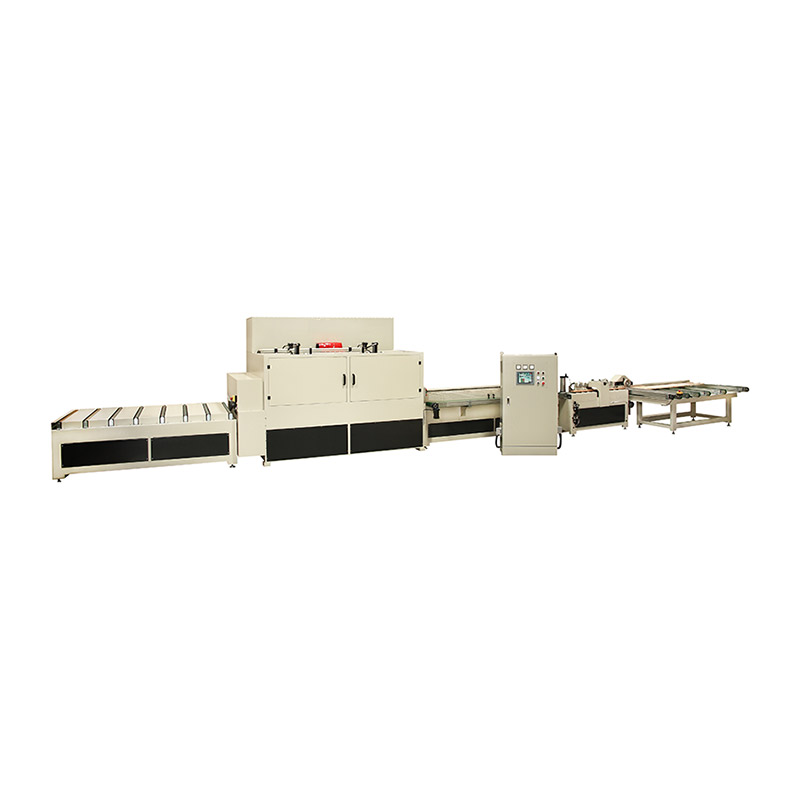

KHL-1030H

High Frequency Wood Board Jointing Machine

- Shorten the manufacturing process and no longer need to do tenon machining.

- The upper plate is configured to provide proper pressure, and the entire plane is pressurized to ensure high flatness of the wood.

- After processing, the flatness of the wood board is high without double-sided planing processing, which reduces wood loss.

- The left and right in and out of the material table, the operation is simple, and can be mass-produced continuously.

- When pressurizing, the high frequency is fast glued to the glue line, and the product quality is extremely high.

- The control system can be designed for PLC control, making the automatic process more convenient.

- The feeding and discharging can be matched with the conveyor belt for continuous feeding and discharging more smoothly.

| Model | KHL-1030H |

| Voltage | 3PHASE 200~600V 50/60HZ |

| Iinput | 50KVA |

| Contribute |

30KW |

| Working Area |

15~50x1250x2500 |

| Oil Pressure |

5HP HYDRAVLIC |

| Control System |

Motor Control By Electronic (Touch Screen) |

| Mechanical Dimensions | 7800x2200x2200 |

| Weight | 5000KG |