YRT-D100

Double End Rectangular Tenoner

Outstanding Features:

- Equipped with a PLC control combined with touch sensing screen for user friendly operation.

- Fully automatic tenoning operation greatly upgrades production output.

- Cutting tenons at both ends simultaneously for greatly increasing efficiency and productivity.

- Designed for producing rectangular and cylindrical tenons.

- The machine is suitable for producing horizontal, vertical and miltered tenons.

- Cutter feed speed is controlled by frequency interter, allowing for variable speed change.

- Equipped with an workpiece magazine for fully automatic operation.

- workpicec feed slideways are euipped with precision linear motion guides, ensuring fast and stable feed motions.

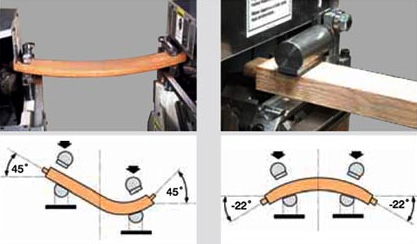

Warpped Workpiece Tenoning

- The workpiece clamps at both sides are adjustable to suit workpiece warpping condition. This permits the machine to perform tenon cutting on a warpped workpiece.

| Model | YRT-D100 |

| Length of cut | 180-1500mm |

| Spindle speed | 9000R.P.M. |

| Maximum tenon width | 100+2R mm |

| Maximum tenon depth | 40mm |

| Minimum tenon depth | 10mm |

| Maximum tenon thickness | 30mm |

| Cutter driver motor | 3Kw×2(4HP×2) |

| Rotation motor | 0.75Kw×2(1HP×2) |

| Head position adjustment motor | 1Kw(1.5HP) |

| Total horsepower | 9Kw |

| Dust hood outlet diameter | Ø60mm×2/Ø100mm×2 |

| Net weight/Gross weight | 2460kg /2915kg |

| Machine dimensions | 3350×2000×1900mm |

| Packing dimensions | 3520×2000×2100mm |