WORLDWIDE

Home / Product Line

Edge Banding Machine | High Quality in Taiwan

Over the years, OAV Equipment and Tools, Inc. achieved continuous growth by closely observing the market in order to produce customer-oriented products. Our A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen is made to the same rigorous quality standards that our commercial customers demand. With the help of A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen, you can easily manage and track your business. Our aim is to create a strong base for the consumers and suppliers in Taiwan and abroad, through which, a perfect chain of demand and supply can be maintained. Our company is a professional manufacturer of A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen, providing OAV MAX370M Automatic EdgeBander, A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen with top quality.

OAV MAX370M Automatic EdgeBander

A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen

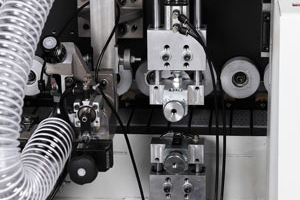

OAV edge bander MAX370M is an industrial choice with CORNER ROUNDING function which brings you the high-quality results on the workpieces.

It coils up to 3mm thick, and strips up to 4mm , this affordable machine is equipped with 1.2kgs capacity glue tank, pre-milling, auto gluing, edge cutting, end trimming, corner rounding, flush trimming, scraping and buffing functions.

Featuring a user-friendly adjustment with numerical indicators as well as TOUCH SCREEN display for all operations. PLC parameter setting & temperature control bring stable and reliable working conditions which raise the quality of your products also saving times.

This best choice is the helper to optimize your investment and take your organizational output and performance to the next level!

It coils up to 3mm thick, and strips up to 4mm , this affordable machine is equipped with 1.2kgs capacity glue tank, pre-milling, auto gluing, edge cutting, end trimming, corner rounding, flush trimming, scraping and buffing functions.

Featuring a user-friendly adjustment with numerical indicators as well as TOUCH SCREEN display for all operations. PLC parameter setting & temperature control bring stable and reliable working conditions which raise the quality of your products also saving times.

This best choice is the helper to optimize your investment and take your organizational output and performance to the next level!

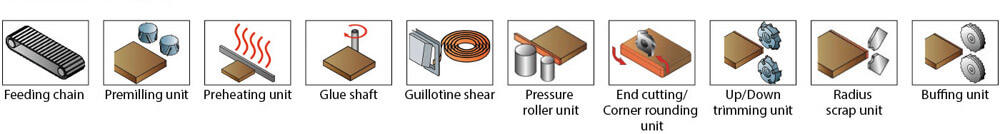

Features :

7" Touch Screen

With management page. Able to operate ALL functions and do micro adjustment Manage page is able to inspect employees working hours, workpiece length, and numbers of workpiece to help business owner manage the performance.

With management page. Able to operate ALL functions and do micro adjustment Manage page is able to inspect employees working hours, workpiece length, and numbers of workpiece to help business owner manage the performance.

Pre-Milling Unit

Two diamond milling heads make sure the workpiece edge is absolutely straight to the material of edge being glued.

Two diamond milling heads make sure the workpiece edge is absolutely straight to the material of edge being glued.

Pressure Roller

The pressure roller unit is to improve the bond between edge and material. It is mechanically spring-loaded and due to the quick setup system, can be adjusted exactly to the required edge thickness.

Guillotine Shears

Able to trim coil edge up to 3mm thickness.

The pressure roller unit is to improve the bond between edge and material. It is mechanically spring-loaded and due to the quick setup system, can be adjusted exactly to the required edge thickness.

Guillotine Shears

Able to trim coil edge up to 3mm thickness.

End Cutting Unit/ Corner Rounding Unit

The unit is amazing with two functions which ensure perfect cutting finish and corner rounding results. It is able to meet any challenge regardless of edge types and thickness.

The unit is amazing with two functions which ensure perfect cutting finish and corner rounding results. It is able to meet any challenge regardless of edge types and thickness.

Up/Down Trimming Unit

The adjustment is quick and easy for radius trimming. 2mm radius tooling is included as standard. The radius scraping unit fine-tunes the edge radius by smoothing trimmed.

The adjustment is quick and easy for radius trimming. 2mm radius tooling is included as standard. The radius scraping unit fine-tunes the edge radius by smoothing trimmed.

Glue Scrap Unit (Optional)

Accomplishing an most favorable appearance by removing the leaked of left glues remained on the edge

Accomplishing an most favorable appearance by removing the leaked of left glues remained on the edge

Buffing Unit

The unit leaves a super finish on ABS and PVC edge, and removes any discoloration on the edges which is especially noticeable when working with dark material.

The unit leaves a super finish on ABS and PVC edge, and removes any discoloration on the edges which is especially noticeable when working with dark material.

Specifications :

| MODEL | MAX370M |

| Feeding speed | 7M/min. |

| Panel Thickness | 12-45mm |

| Edge Thickness | 0.4-3mm |

| Mini. Panel width | 90mm |

| Mini. Panel length | 170mm |

| Working table height | 856mm |

| Extensible support width | 560mm |

| Extension connector Φ in mm | Φ4" (105mm)X3 |

| Total kW | 5.4 kW-3ph / 6.2kW-1ph |

| Pre-milling | 12000 rpm |

| End trimming | 10500 rpm |

| Up/down trimming/ Corning rounding | 12000 rpm |

| Buffing | 3400rpm(60HZ)/2800rpm(50HZ) |

| Overall Size (LXWXH) | 3300x1200x1200mm |

| Weight, N.W./G.W. | 500/632kgs(N.W./G.W.) |

| Container Qty' (20'/40') | 6/12 sets |

| Power (KW) of each motor | |

| Feeding Motor | 0.75kW(3ph), 0.94kW(1ph) |

| Pre-milling | 1.5kW |

| Pre-heating | 0.125kW |

| Glue spindle motor | 0.25kW |

| End trimming motor /Corning rounding Motor | 0.37kW |

| Upper/lower trimming motor | 0.55kW(3ph), 1.13kW(1ph) |

| Upper/lower buffing motor (each) x2 | 0.12kw (3ph), 0.18kw(1ph) |

| Glue Pot heating (5 elements) | 1.315 kW |

Our products have always been known for quality, reliability and solid performance, making OAV Equipment and Tools, Inc. becomes the most specified brand in the A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen business. We can manufacture A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen that meets specific technical requirements. If you are looking for OAV MAX370M Automatic EdgeBander, A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen, you are in the right place. At OAV Equipment and Tools, Inc., you will find every kind of A compact edgebanding machine within pre-milling, corner rounding and the user-friendly touch screen that you can think of, with something for all kind of business.