WORLDWIDE

首页 / 产品介绍

单板薄片加工机

仕兴机械工业股份有限公司专注于专业单板薄片加工机领域,我们以多年累积的核心技术及经验,配合顾客的各种需求,提供高品质的单板薄片加工机 产品服务。我们提供单板薄片加工机详细产品服务资讯,欢迎您利用表单方式与我们联系,我们将竭诚为您服务。

UltiMate 薄片机

横向单板薄片拼接机

The UltiMate crossfeed splicing machine is designed for glue-spliced joint for long and panel-sized veneer faces. The pre-glued veneer strips are fed into the machine manually with feeding stoppers for fast and easy operation. The integrated cut-to-size clipper at the outfeed section is for the designed-width faces.

Operators can also select the endless splicing model for jointing certain numbers of veneer strips. The production output of the crossfeed splicing machine is approximately 6 ~ 7 times faster than the longitudinal splicing machine. Together with our Double Sided Veneer Glue Applicator, GlueMate, and Veneer Fanning Machine, FanningMate, a full set of veneer splicing line is completed.

VeneerPlus, LVS-1250 系列薄片机

纵向单板薄片拼接机 内建自动布胶系统

The VeneerPlus is particularly suitable for the furniture industry and automatic production runs. To accomplish this work, a specially designed gluing device is mounted between the feeding rollers and transporting conveyors. This enables users to feed veneers right after veneer edges are cut straight eliminating the pre-gluing process. The infeed rollers will accurately align the veneer to the gluing unit and then transport the glued veneers to the heating section. In this case, the veneer gluing and splicing work can be accomplished within one single machine.

Standard Accessory - Cooling System for Glue-pot

To extend the pot-life of the mixed glue, a cooling system is mounted on the bottom of the glue-pot.

VeneerMate LVS-1250 系列薄片加工机

纵向单板薄片拼接机

The VeneerMate is designed to splice high end veneers. This machine enables users to accurately and firmly bond the veneer edges with no visible joint line.

As opposed to the traditional splicing machine equipped with stitching threads or taping papers, this VeneerMate Longitudinal Veneer Splicer applies specially designed heating and pressing mechanisms eliminating visible joint lines on the surface of wood piece and resulting in a perfect seamless joint from one single pass.

As opposed to the traditional splicing machine equipped with stitching threads or taping papers, this VeneerMate Longitudinal Veneer Splicer applies specially designed heating and pressing mechanisms eliminating visible joint lines on the surface of wood piece and resulting in a perfect seamless joint from one single pass.

VeneerSolid 950 薄片加工机

纵向单板薄片拼接机

The VeneerSolid 950 is an entry-level machine ideal for "custom shops" with lighter application requirements (less than 8 hours run time per day). And this VeneerSolid 950 also meets all the splicing performance features of INNOVATOR veneer splicing machine.

This machine enables users to avoid troubles caused by the traditional glue-thread splicing method. This machine is capable of splicing components for Diamond Match applications. The infeed rollers will accurately align the veneer by means of photocell censer to avoid uneven alignment at the front end of veneers.

This machine enables users to avoid troubles caused by the traditional glue-thread splicing method. This machine is capable of splicing components for Diamond Match applications. The infeed rollers will accurately align the veneer by means of photocell censer to avoid uneven alignment at the front end of veneers.

GlueMate 薄片加工机

双面单板薄片自动布胶机

The GlueMate ensures precise application of adhesive to the edges of veneer bundles eliminating airborne contaminants and operation inconsistency. Both Urea based or PVAc glue work well with GlueMate. Coupled with Innovator's both crossfeed and longitudinal splicers, a perfect veneer splicing job can be achieved.

Standard Accessory - Cooling System for Glue-pots

To extend the pot-life of the mixed glue, a cooling system is mounted on the side of each glue-pot.

Standard Accessory - Cooling System for Glue-pots

To extend the pot-life of the mixed glue, a cooling system is mounted on the side of each glue-pot.

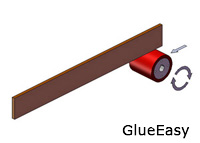

GlueEasy 薄片加工机

单面单板薄片自动布胶机

SINGLE SIDED VENEER EDGES GLUE APPLICATOR

Model: GlueEasy

The GlueEasy, veneer edges gluing unit, is designed for providing a precise and reliable veneer edges gluing output for pre-gluing splicing work. Unlike traditional hand-gluing methods, the veneer package is placed vertically with pneumatic pressing mechanism from two sides to avoid excessive or uneven glue applied onto veneer edges.

This allows operators to have "precise and even" glue applied resulting in a seamless and clean jointing outcome. Coupled with INNOVATOR'S both crossfeed and longitudinal splicers, a perfect veneer splicing work can be achieved.

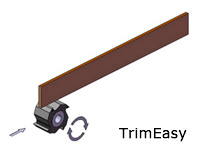

VENEER EDGES TRIMMING MACHINE

Model: TrimEasy

The TrimEasy, veneer edges trimming unit, is designed for providing a 90-degree jointing angle on the jointing face of veneer edges for the strongest bonding output. Similar principle as our GlueEasy, the veneer package is placed vertically with pneumatic pressing mechanism from two sides followed by the trimming cutter passing through the veneer bundle edges. The TrimEasy mechanism can be mounted together with the GlueEasy machine resulting in a combination of gluing and trimming work for the high quality splicing requirements.

FanningMate 薄片加工机

单板薄片展开机

The FanningMate is designed to fan pre-glued veneer bundles. Unlike manual fanning, this fanning machine offers a solution to avoid the pre-glued veneer leaves from sticking together. The FanningMate is usually positioned as the second station after the pre-glued veneer bundle has exited our GlueMate. It can also be employed as a "stand alone" station after a manual pre-gluing process.

CutMate 2800 & 3200 薄片加工机

单板薄片剪切机

Thanks to our partner, SAVI Industries from Denmark, INNOVATOR Machinery is now building SAVI guillotines in Taiwan with the original technology and know-how being transferred.

F-15 薄片加工机

F-15 薄片切割框锯机

Designed For Profitable Production

The F15 Thin-Cutting Frame Saw from Mick & Jack is designed and engineered to enhance the high efficiency and high accuracy cutting. In addition to provide various cutting modes, the F15 also features great material -cost saving that creats profits for customer. The machine is equipped with a micro- computer control for maximum operational convenience.

Various Sawblades For Choice

The F15 Thin-Cutting Frame Saw from Mick & Jack is designed and engineered to enhance the high efficiency and high accuracy cutting. In addition to provide various cutting modes, the F15 also features great material -cost saving that creats profits for customer. The machine is equipped with a micro- computer control for maximum operational convenience.

Various Sawblades For Choice

- Upon request, the machine can be supplied with steel welded sawblade or supported steadily, ensuring T.C.T. sawblade for choice.

- The customer may choose various sawblade thickness from 1.1 to 1.4 mm to suit various wood materials.

欢迎您透过与我连络将单板薄片加工机的洽询需求传送给我们,我们会尽快与您联系。建议您可同时参考以下相关产品目录。

相关产品目录